News

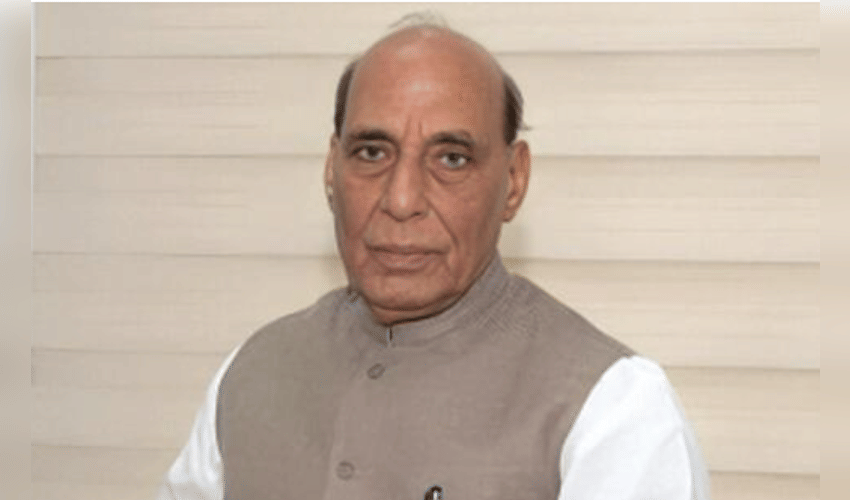

Manufacturing aero engines is a major challenge, says Defence Minister Rajnath Singh.

Defence Minister Rajnath Singh has highlighted that despite India’s advancements in various critical defence sectors such as missile technology, submarines, aircraft carriers, artificial intelligence, drones, cyber defence, and hypersonic systems, the manufacturing of aero engines continues to be a significant challenge. His remarks come at a time when the Light Combat Aircraft (LCA) TEJAS MK-1A program, which is crucial for the Indian Air Force (IAF), is facing delays due to the delayed delivery of F404-IN20 engines from GE Aerospace. While India has made progress with its indigenous Kaveri engine project, Singh acknowledged the substantial technology gap in aero engine manufacturing that the country still faces.

To bridge this gap, India is working closely with global companies such as Safran, GE, and Rolls Royce to build its domestic capabilities. A version of the Kaveri engine, initially developed for fighter jets, is now being adapted to power armed drones. GE Aerospace has already delivered the first of 99 F404-IN20 engines to Hindustan Aeronautics Limited (HAL) for the MK-1A fighters, and more deliveries are expected to fulfill the IAF’s order for 83 MK-1As, with plans for additional aircraft.

Additionally, there are ongoing negotiations between HAL and GE Aerospace for the joint production of F414 engines in India for the advanced TEJAS MK-2 program. This deal, valued at around $1 billion, would include an 80% transfer of technology, significantly enhancing India’s domestic manufacturing capabilities. Singh also mentioned that work is underway to develop engines for India’s ambitious Advanced Medium Combat Aircraft (AMCA), with the Cabinet Committee on Security approving a ₹15,000 crore project to design and develop five twin-engine prototypes.

However, India’s pursuit of self-reliance in aero engine manufacturing is hindered by several challenges, including the technological complexity of producing advanced materials like single-crystal turbine blades and thermal barrier coatings, which the country has struggled to produce at the necessary quality and scale. There is also a lack of sustained, high-level investment and state-of-the-art testing facilities, leading to delays and continued dependence on foreign suppliers. Bureaucratic inefficiencies and limited collaboration with global experts have slowed progress, although new partnerships are helping to address this. Additionally, there is a shortage of trained personnel and inconsistent R&D in advanced technologies, with projects often moving forward only when driven by immediate military needs.

Singh emphasized the importance of overcoming the mindset of relying on imports and stressed the government's focus on reducing import dependency, strengthening India’s defence industrial complex, and boosting export potential. India's defence production is expected to surpass ₹1.6 lakh crore in 2024, with a target of ₹3 lakh crore by 2029. Defence exports have reached a record ₹23,622 crore in 2024-25, with plans to double this figure by 2029. While India has made notable progress in several defence sectors, the manufacturing of aero engines remains a critical bottleneck. The government is addressing this challenge by increasing funding, fostering international collaborations, and pushing for indigenous innovation, with the aim of transforming India into a global hub for defence manufacturing and exports.

Disclaimer: This image is taken from Hindustan Times.